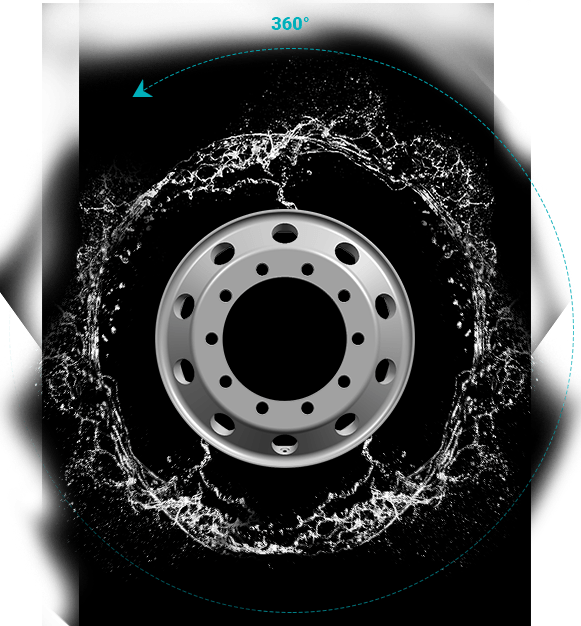

truck wheel

Advantages of Yueling products

High Strength

The deformation resistance of the aluminum alloy wheel is 5 times more than steel wheels, and the aluminum alloy wheels are much stronger. It is 3.4 times more flexible than steel wheel, Stronger flexibility make the wheels not so easy to break.

Light Weight

It is about 50% less weight per wheel compared to steel wheels, each heavy duty truck(24 wheels) can reduce by about 665kg. Reduce tire wear, Reduce brake system wear, Reduce Fuel Consumption.

Economical Price

It can reduce operating cost, extend the life of tire and brake system and reduce oil consumption. It can also load more goods to increase income. And the recycling value of waste wheel is objective.

Comfortable

All surface of wheels use highly processed and the product roundness is very good. It improve the stability of the vehicle.

5 Years Warranty

High production efficiency, suitable for mass production.The product is guaranteed for 5 years with no limit on mileage.Wheel hub quality problems caused by flat and broken tires, we compensate tires, 24 hours online service.

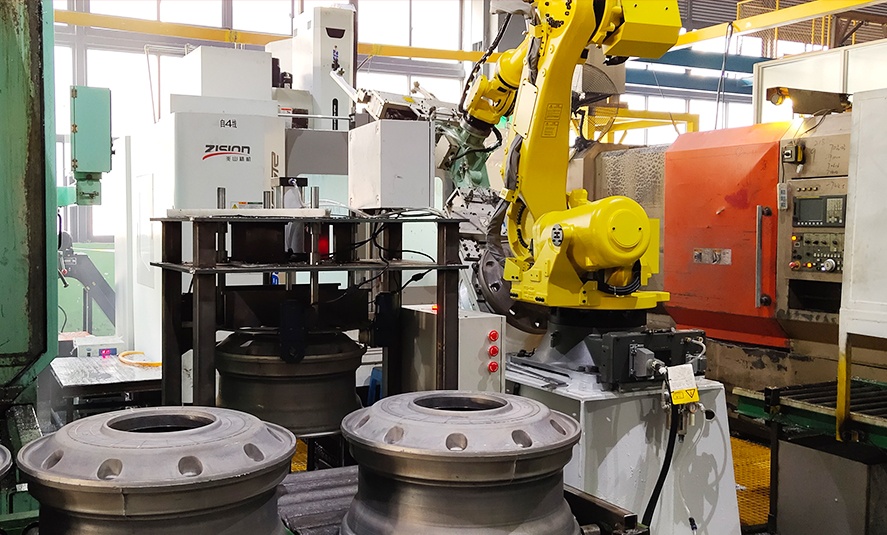

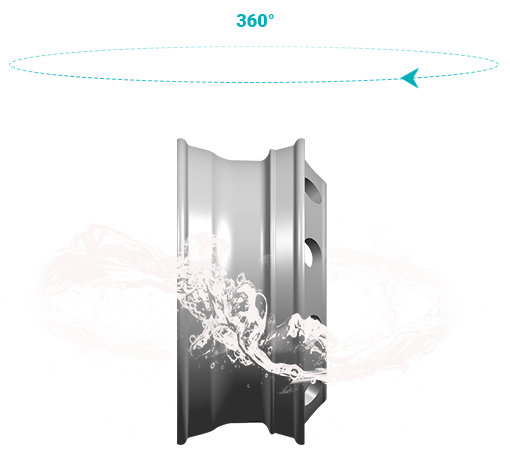

Vertical bilateral rotation flow forming

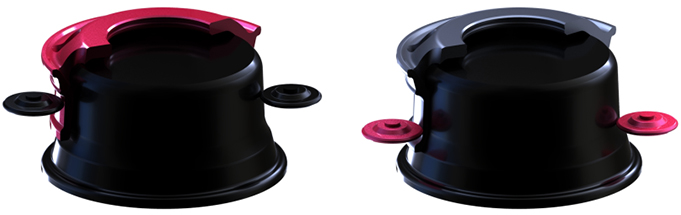

Water cooling technology

New revolutionary multi-dimensional high pressure water-cooled rotary forging truck wheels.

The use of the exclusive allocation of high efficiency alloy refinement modifier, through the liquid aluminum trace element ratio to strengthen, effectively improve the microstructure defects of the alloy, greatly enhance the mechanical properties of aluminum alloy.

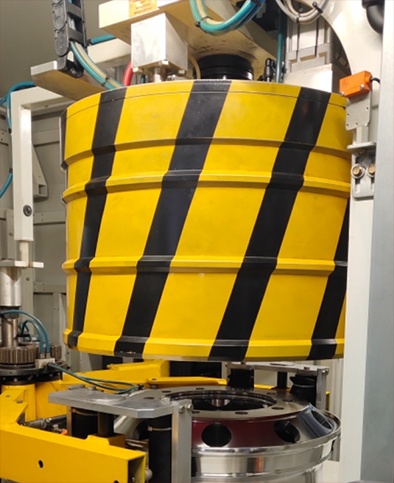

Original stereo water-cooled 720 ° multidimensional high pressure technology, through the custom design of cooling control system can realize the cooling parameters of 720 ° omni-directional three-dimensional adjustment, accurate control, cooling rate and cooling efficiency three times faster than the average cooling system, saving energy and reducing consumption, and greatly reduce casting defects, solve the radial forging truck wheels disk poor mechanical properties, the disadvantage of PCD hole site is easy to break.

The rim adopts the vertical condensation rotary forging once forming technology, through a multi-axis rotary wheel to complete the rim rotary forging, rotary forging synchronous forming, the rim is really round with high precision, excellent dynamic balance performance, and the mechanical properties of the rim are equal to the forged truck wheels.

720° all-around water cooling

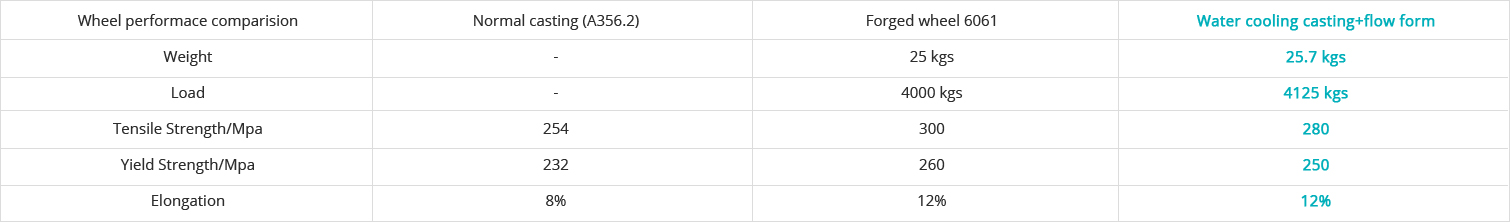

process contrast

Yueling water cooling flow formed truck wheel

The strength and toughness close to forged wheel,however,the price is casting wheel's price

Production Process Introduction

Quality Control

Full automatic radial fatigue testing machine

German VDH full automatic Helium Mass Spectrometer Leak Detector

Full automatic bending fatigue testing machine

0 years

40 years of experience

0 employees

More than 1600 employees

0 m2

The building area of the factory is

more than 105,000 square meters

Hengjing Factory

Hengjing Industrial Zone, Zeguo Town, Wenling, Taizhou, Zhejiang

Chayu Factory

Chayu Industrial Zone, Zeguo Town, Wenling, Taizhou, Zhejiang

Danya Factory

Danya Industrial Zone, Zeguo Town, Wenling, Taizhou City, Zhejiang Province

Its total assets are nearly 1.17 billion yuan

In 2019, Yueling achieved mass income 967 million yuan

The company has 8 national invention patents, 138 patents for utility models and 98 design patents

It has an annual production capacity of 4 million high-quality gravity casting aluminum wheels, 2.3 million low-pressure casting aluminum wheels and 2 million high-quality spinning casting aluminum wheels